Commodity Number :

393-511-522-040

Commodity Name :

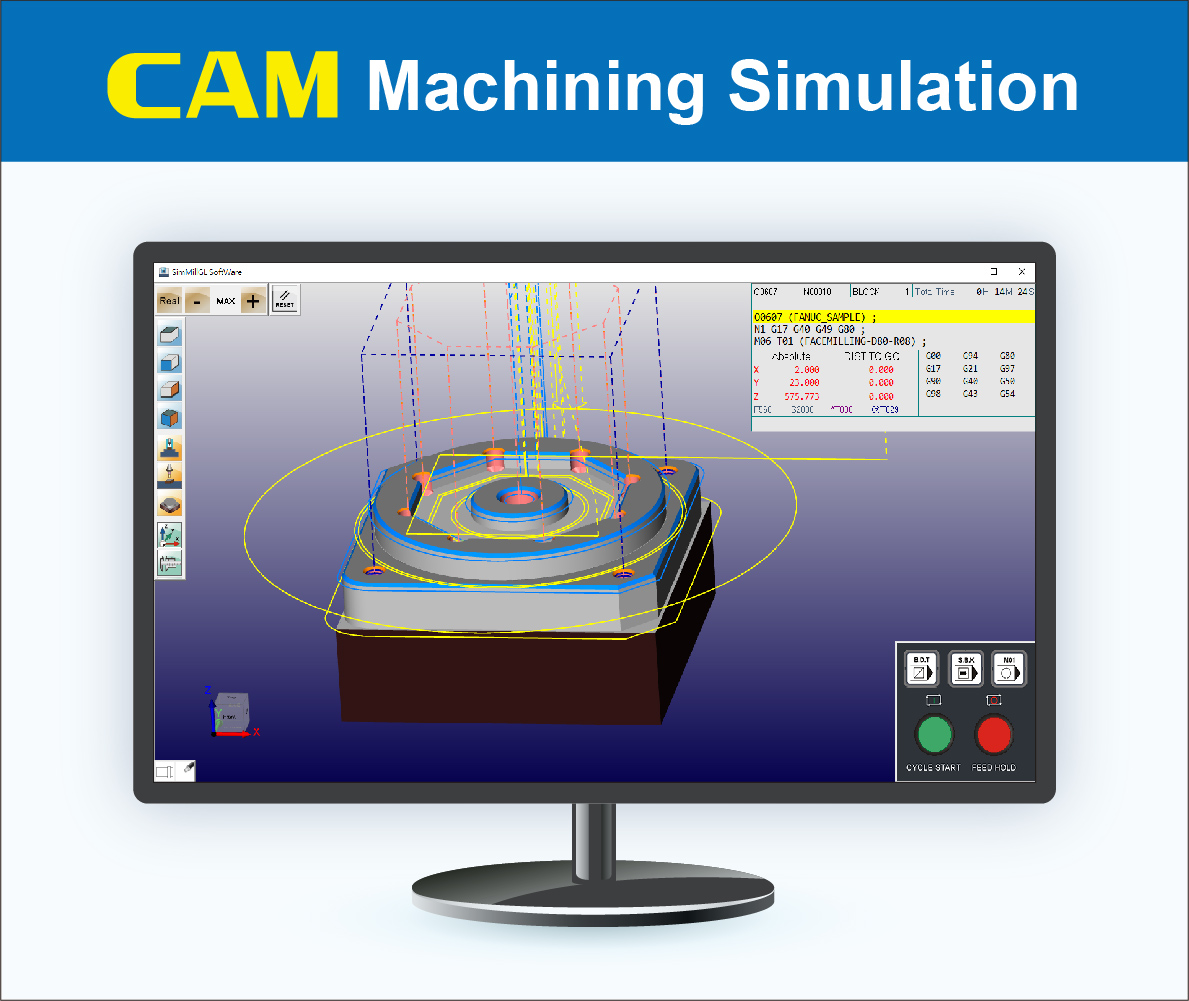

FrankCAM Mill 2022 Professional Version

Commodity Introduction :

Guided-steps CAD/CAM with Machining Simulation including tool path verification and machining time. Excellent tool for learning CAD/CAM and verifying with simulation.

Use Version :

Subscription Plan:

Commodity Price :

Product Specifications

1 FrankCAM Drawing

1.1 Drawing Function

(1) Point Function: coordinate, center, intersection, Polar, middle, on Arc, on Circle

(2) Line Function: two points line, Angle, Angle & Tangent Arc, through Point & tangent Arc, two Arc tangent, Shift

(3) Circle Function: center & radius, Two Points & radius, through point & tangent, through point & tangent circle, Tangent two lines, tangent Line & Arc, Tangent two Arcs, Begin Middle End, two points on Diameter, center point & on circle, Center & tangent, Wizard for Drawing Circle

(4) Polygon: Rectangle, Polygon

1.2 Cut and corner: auto section, section, break, cut, corner-chamfer

1.3 Modify Drawing: Workpiece Coordinate Zero Point Shift, Absolute Shift, Incremental shift, rotate, mirror, Offset Contour, Scaling

1.4 Layer management: add, delete, rename, display

1.5 Import DXF file:

(1) Import option: point, line, circle, arc, input same layer

(2) Unit convert option: keep (1:1), Inch to mm, mm to Inch

1.6 Dimension: radius, diameter, two line angle, point, distance to X-axis, two point distance, two point horizontal distance, two point vertical distance

Professional Version Additional Features

1.1 Import DXF file:

(1) Import selection: curve

2 Machining Process

2.1 Material setting: length, width, height

2.2 Milling Tools: Ball, Drill, Corner Radius, End Mill, Face Mill, Tapping, Chamfer, Boring

2.3 Tool Magazine setting:

(1) Magazine selection: set tool used on machine

2.4 Milling process:

(1) Rough milling: Surface, Outer, Pocket, Island

(2) Outline finishing: Contour, Profile Chamfer

(3) Hole machining: Drilling, Boring, Reaming, Tapping

(4) Other: Arc Surface

2.5 Rough milling

(1) Face:

(a) Milling type: spiral, ZigZag, single direction

(b) Advance section setting

(c) Start position of entry and retract, first tool direction, safe distance setting

(2) Outer, Pocket:

(a) Milling type: cut along contour, ZigZag

(b) Advance section setting

(c) Entry type setting: direct, ramp, helix

(d) Entry/ retract setting

(3) Island:

(a) Milling type: cut along contour, ZigZag

(b) Advance section setting

(c) Entry type setting: direct, ramp, helix

2.6 Finishing:

(1) Contour:

(a) Advance section setting

(b) G41 G42 tool offset option

(c) Entry/ retract setting

(2) Profile Chamfer:

(a) G41 G42 tool offset option

(b) Entry/ retract setting

2.7 Hole Cycle:

(1) Drilling:

(a) Fanuc, Mitsubishi cycle mode: G73 Peck Drilling Cycle, G81 Drilling Cycle, G82 Drilling Cycle Dwell, G83 Deep hole Peck Drilling Cycle

(b) Siemens cycle mode: CYCLE81 Center Drilling, CYCLE82 Drilling, CYCLE83 Deep hole drilling

(c) TNC 530 cycle mode: CYCLE200 Drilling, CYCLE203 Universal drilling, CYCLE205 Universal pecking

(2) Boring:

(a) Fanuc, Mitsubishi cycle mode: G76 Fine Boring Cycle, G85 Boring Cycle, G86 Boring Cycle, G87 Boring Cycle Back Boring Cycle, G88 Boring Cycle, G89 Boring Cycle

(b) Siemens cycle mode: CYCLE85 Reaming, CYCLE86 Boring

(c) TNC 530 cycle mode: CYCLE201 Reaming, CYCLE202 Boring, CYCLE208 Boring Milling

(3) Tapping:

(a) Fanuc, Mitsubishi cycle mode: G84 Right-handed, G74 Left-handed

(b) Siemens cycle mode: CYCLE84 Rigid tapping, CYCLE840 Tapping

(c) TNC 530 cycle mode: CYCLE206 New Tapping, CYCLE207 New Rigid Tapping, CYCLE208 Chip Tapping

2.8 Process setting: display cutting path, refresh, insert, edit, Delete Process

2.9 Machining Contour:

(1) Contour start, Approach start point, Approach extension line, Retract End point, Retract extension line and drag function

(2) Contour direction selection, auto connection function

(3) Tool offset option

(4) Offer Sketch extension function, control Approach and Retract path without additional drawing

Professional Version Additional Features

2.1 Tool setting: add, modify, delete

2.2 Tool magazine setting:

(1) Common tool magazine: set common tool magazine to choose for use

(2) Import/export tool magazine: Import and export tool magazine

2.3 Arc surface machining:

(1) Arc direction support ZX, YZ plane arc

(2) Cutting section and Milling type setting

(3) Approach / Retract start point and First Cutting direction setting

3 Cutting Simulation

3.1 CNC program dynamic cutting simulation

3.2 3D solid construction: tool, workpiece

3.3 Collision detection: tool and material

3.4 Simulation speed control: 50%, 100%, 250%, 500%

3.5 Standard view: Top view, Front view, Side view

3.6 Common adjustment view: machine view, cutting view, material view

3.7 Free operation view: shift, rotate, zoom in/out

3.8 Machine type: Fanuc (1 Post)

Professional Version Additional Features

3.1 Simulation speed control: 10%, 50%, 100%, 160%, 250%, 500%, 900%, 990%, MAX

4 NC Code Generation

4.1 Post CNC Program

(1) Sequence number: manually set start value and interval size

(2) M08/M09 function

(3) Transfer the process option: check the process to be transferred

4.2 Controller type: Fanuc, Mitsubishi, Siemens, Heidenhain

4.3 Coordinate system: Switch coordinate plane setting

XY plane(G17), ZX plane (G18), YZ plane (G19)

4.4 Program out parameter setting:

(1) Self-set the program of exclusive machine model

(2) Self -design beginning of process and end of process

Professional Version Additional Features

4.1 Machine type: Fanuc, Siemens, Mitsubishi (3 Post Option)

None