Commodity Number :

392-511-524-040

Commodity Name :

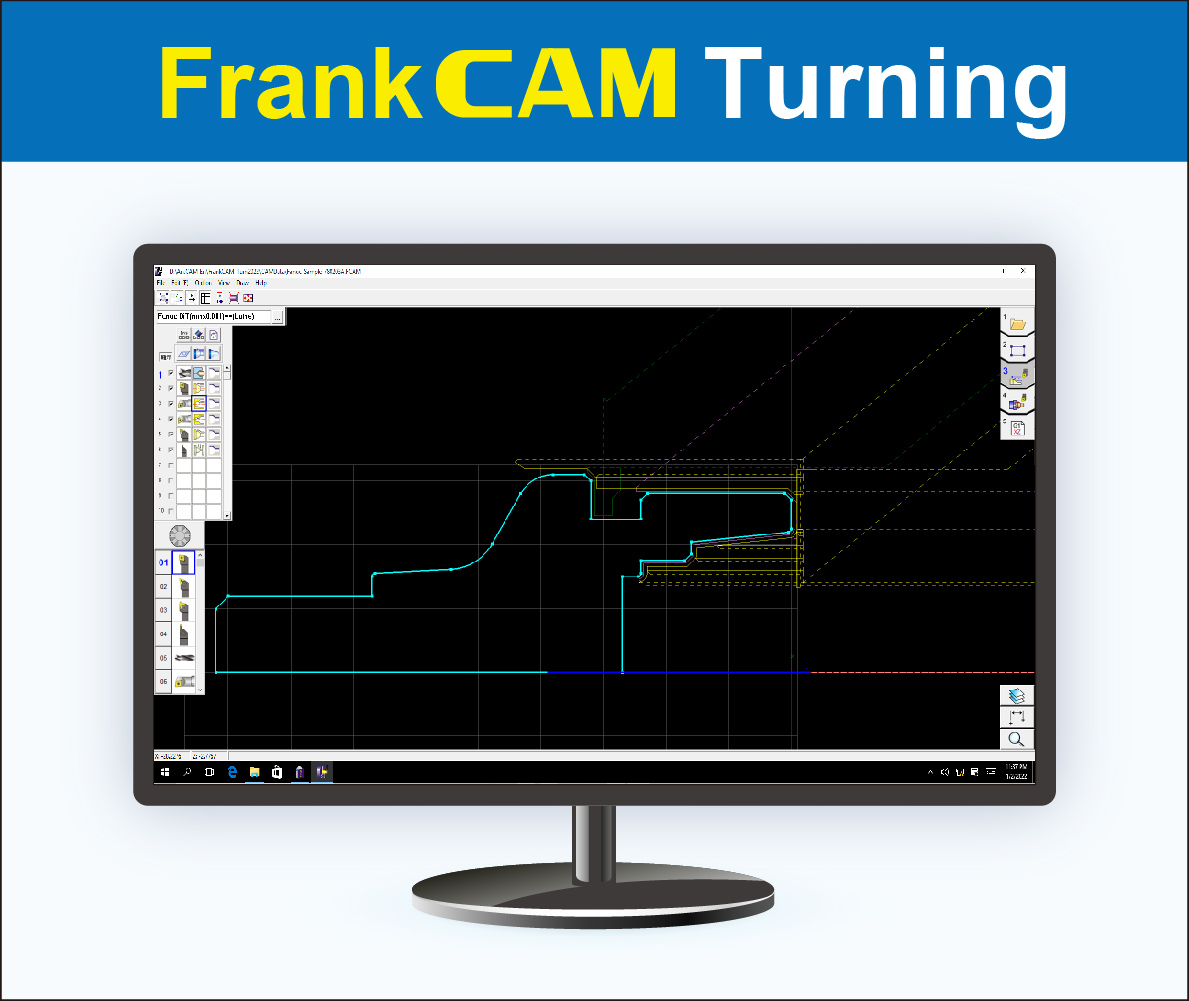

FrankCAM Turn 2024 Professional Version

Commodity Introduction :

Guided-steps CAD/CAM with Machining Simulation including tool path verification and machining time. Excellent tool for learning CAD/CAM and verifying with simulation.

Use Version :

Subscription Plan:

Commodity Price :

Product Specifications

1 FrankCAM Drawing

1.1 Drawing Function

(1) Point Function: coordinate, center, intersection, Polar, middle, on Arc

(2) Line Function: two points line, Angle, Angle & Tangent Arc, through point & tangent Arc, two Arc tangent, Shift

(3) Circle Function: center & radius, Two Points & radius, through point & tangent, through point & tangent circle, Tangent two lines, Tangent Line & Arc, Tangent two Arcs, Begin Middle End, two points on Diameter, center point & on circle, Center & tangent, Wizard for Drawing Circle

1.2 Cut and corner: auto section, section, break, cut, corner-chamfer

1.3 Modify Drawing: Workpiece Coordinate Zero Point Shift, Absolute Shift, Incremental shift, rotate, mirror, Offset Contour, Scaling

1.4 Layer management: add, delete, rename, display

1.5 Import DXF file:

(1) Import selection: point, line, circle, arc, input same layer

1.6 Dimension: radius, diameter (X axis), two line angle, point, distance to X-axis, diameter, distance to Y-axis, two point distance, two point horizontal distance, two point vertical distance

Professional Version Additional Features

1.1 Profile Master

(1) Outline: G01 line, G02 CW Arc, G03 CCW Arc, From Turning Figure Expert

(2) G01 line: Chamfer C, Corner R, Angle coordinate function

(3) G02, G03 Arc: Chamfer C, Corner R

(4) Turning Master: built-in 400 turning graph pattern, can import workpiece contour

1.2 Import DXF file:

(1) Import selection: curve

(2) Unit convert option: keep (1:1), Inch to MM, MM to Inch

2 Cutting Machining

2.1 Material setting: length, width, height

2.2 Turning Tools: Diamond (80 °, 55 °, 35 °), Triangle (60 °), Thread, Groove, Corner Radius, Drill

2.3 Tool Library setting:

(1) Tool selection: set tool used by machine

2.4 Cutting process: rough, pattern, finish, groove, straight groove, thread, drilling, tapping, cutting off

(1) Tool change point setting: set tool change position to reduce collision

(2) Middle safe point, approach safe point, retract safe point

(3) Approach / retract extension line: can choose contour itself or next contour

2.5 Rough cutting process: External, Internal, End Face

(1) According to requirement to choose axial or radial cutting

(2) Support G71, G72 canned cycle function for Fanuc and Mitsubishi

(3) Support G85 canned cycle function for Okuma

(4) Time and depth setting for cutting

2.6 Pattern process: external, internal, end face

(1) According to requirement to choose axial or radial cutting

(2) Time and depth setting for cutting

(3) Approach/ retract absolute coordinate or relative coordinate setting

2.7 Finish cutting process: external, internal, end face

(1) According to requirement to choose axial or radial cutting

(2) Workpiece contour directly calculate for tool nose offset

(3) Can use G41, G42 to do compensation

2.8 Groove process: external, internal, end face

(1) Support G74, G75 canned cycle function for Fanuc, Mitsubishi

(2) Support G73, G74 canned cycle function for Okuma

(3) Cutting style: cutting depth, peck cut

(4) Working order: from Middle to side, from side to Middle

2.9 Thread: universal type, particular type (optional purchase)

(1) Support G32, G92, G76 cycle function for Fanuc

(2) Support G33, G78, G76 cycle function for Mitsubishi

(3) Support G31, G33, G71 cycle function for Okuma

2.10 Drilling

(1) Support G74 Drill for Fanuc

(2) Support G74 Drill for Okuma

2.11 Tapping : G32 tapping, G84 tapping cycle

2.12 Cutting off: support cutting off setting, post cutting off program

2.13 Process setting: display all cutting path, redo, insert, edit, delete process

2.14 Contour

(1) Contour start, Approach start point, Approach extension line, Retrace End point, Retract extension line etc. Drag function

(2) Contour direction selection, auto connect function

(3) Offer Sketch extension function, control Approach and Retract path without additional drawing

Professional Version Additional Features

2.1 Tool setting:

(1) Add, modify, delete

(2) Self-setting key in limit tool cutting angle

(3) Insert angle, cutting angle, auto overcut judgment, arc overcut judgment

2.2 Tool Library setting:

(1) Common tool library: set common tool turret to choose for use

(2) Import/Export tool library: Import and Export built tool library

2.3 Rough cutting process:

(1) Support G85 rough cutting mode No.1 cycle function for Okuma

(2) External rough increase re-approach clearance design to reduce insert breakage caused by chips stuck

(3) G71 Canned Cycle II, multi Pockets in stock removal Turning (10 concaves)

(4) Face cutting selection, divide into three parts to set cutting feedrate to protect tool from breakage

(5) Finish face cutting, support add user NC code

2.4 Pattern:

(1) Support G73 forming process cycle function for Fanuc and Mitsubishi

(2) Face cutting selection, divide into three parts to set cutting feedrate to protect tool from breakage

(3) Finish face cutting, support add user setting

2.5 Finish process:

(1) Can select Angle command, chamfer C, corner R

(2) Auto corner R on Acute angle

(4) Face cutting selection, divide into three parts to set cutting feedrate to protect tool from breakage

(5) No drag function to protect groove from force in one direction

(6) Finish face cutting, support add user setting

2.6 Straight: Single Straight Groove, Single Internal Straight, Single Face Straight

(1) Height equal, higher right, higher left, pattern selection

(2) Straight groove and internal straight multi groove function, support post subprogram selection

(3) Groove approach selection of multi levels to satisfy each workpiece figure cutting

(4) Auto re-approach clearance function to reduce insert breakage from clips stuck while approach and extend tool life

2.7 Thread: taper type

2.8 Drilling :

(1) Support G01 High Speed Drill, G83 Deep Hole Drill cycle for Fanuc

(2) Support G01 High Speed Drill for Okuma

2.9 Cutting off: Can set chamfer parameter, and support user self-set auxiliary program

3 Cutting Simulation

3.1 Tool Bar

(1) Simulation display: cutting path, solid, solid section, tool, axes, zoom in, zoom out, initial view, message switch, clean screen

(2) Speed control: 50%, 100%, 250%, 500%

(3) Process control: Search Sequence, Reset, Cycle Start, Single Block, Option Block Skip, M01 Optional Stop

3.2 View control: move upward, downward, leftward, rightward, zoom in, zoom out

3.3 Process control: Search Sequence, Reset, Cycle Start, Single Block, Option Block Skip, M01 Optional Stop

Professional Version Additional Features

3.1 Tool Bar

(1) Simulation display: workpiece profile

(2) Speed control: 10%, 50%, 100%, 160%, 250%, 500%, 900%, 990%, MAX

3.2 View control: Three-D viewpoint, front viewpoint, up viewpoint, right viewpoint, viewpoint

3.3 Export DXF file

3.4 Dimension: Radius, diameter (X axis), distance to X axis, point, two line angle, diameter, distance to Y axis, two point distance, two point horizontal distance, two point vertical point

4 NC Code Generation

4.1 Post CNC Program

(1) Sequence number: can choose simple sequence number, manually set start value and interval size

(2) Transfer the process option: check the process to be transferred

4.2 Controller type: Fanuc, Mitsubishi, Siemens (ISO mode),Okuma

Professional Version Additional Features

4.1 Program generation parameter setting:

(1) Can self-set program process for specific controller type

(2) Can self-design program head, program end, operation start, operation end